-

Industrial Valves

Industrial valves are a large set of manufacturers where mechanical devices are set up as regulators of gaseous, liquid, and other systems. These are called valves. For example, gate, diaphragm, plug, and pressure reliefs control different types of flow by its operated machines. There are large bulk of Industrial Valve located in India with the enormous type of block and blood valves that controls blood flo w and play a major role in petrochemical sectors. Like instrumentation valves and pressure valves, other types of valves are also widely available in the country.

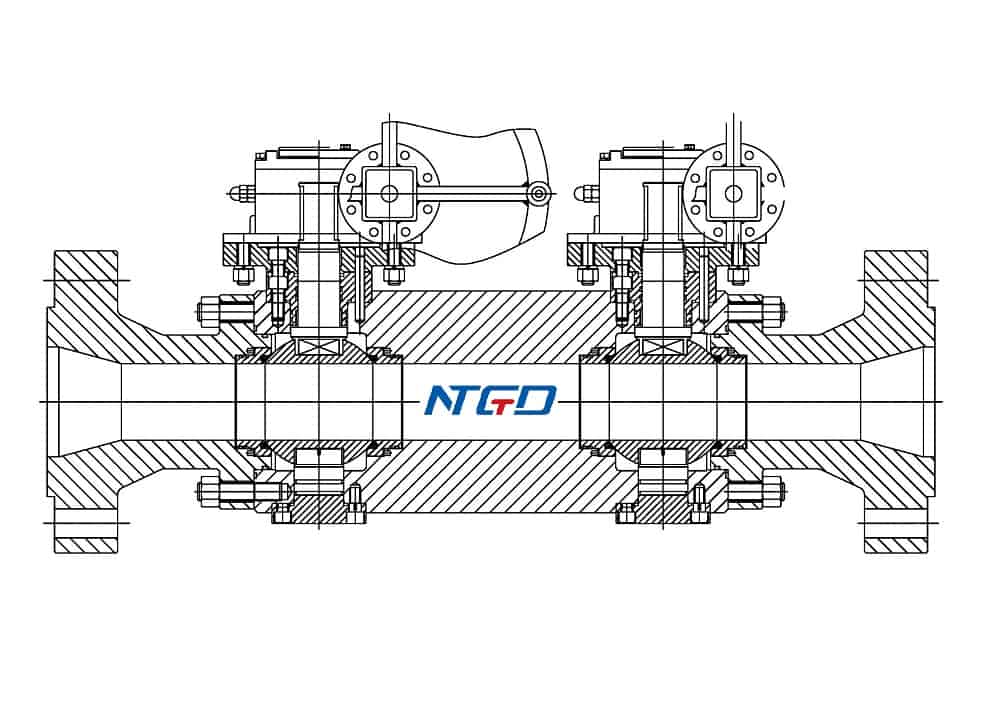

Trunnion Ball Valve

Trunnion ball valve is another enormous valve invention in the industry which use to control flow by its hollow shaped quarter ball in front of the valve mechanism.

- How it works-

- The ball in the machine is linked to the stem (operator or long support on the top of the machine), and it is also connected to the trunnion of the machine, which is in a hollow cylindrical shape.

- When the machines are on, the ball connected to both things rotates in its position.

- The rotation of the ball in the machine works as a principles body and generates its own functions.

- For what purposes they are used-

- The trunnion ball valves are used for on-off controls, which are gate valves and globe valves.

- It is also used for control application of machines

- To control pressure extensively.

- Advantages of Trunnion Ball Valve are

- This machine eases the steps of operation.

- Presents better performance and services as it minimizes the fluids.

- Either the pressure is low or high, the trunnion ball valve can perform protectively and efficiently.

Double Block and Bleed Valves (DBB)

The Double block and bleed valve are two in one automated machine set up in the maximum number of industries. This machine blocks the flow of fluid by its needle and ball valves activated in the machine.

- For what purposes they are used-

- To stop or pause the flow of fluid from where the work is being done.

- Used for petrochemical and valves industries

- How it works-

- The two valves in the machine should be closed, and the bleeder would be opened to start its functions.

- Before any pressure of downstream valves, the first half of the valves will drain the flow.

- Advantages of DBB

- Its uses and functions can be compared to a high-level isolation machine.

- This machine is compactum in the valve industry.

- Personal advantages are- it reduces weight, cost, and high exposure.

- It is a time-saving machine as it works fast.

To be specific, these valves machines efficiently stop gas or liquid flow with high capacity, functions, and stems.

In conclusion, these valve machines are the ultimate stoppage to any form of fluid, liquid, or gas opted in an industry. The trunnion valve machine costs approx. 15,000 and Double block and blood valves cost 1,200 to 1,500 approx. These machines are affordable, and anyone can start small scale industries with the valves machines, which are beneficial and on-demand machines for industries in today’s rate.

votre commentaire

votre commentaire

-

Valves are generally divided into several types to reach their particular specifications and functions. Now, a deep look at the ball valve is taken here. Similar to other valves, a ball valve is usually used to control the flow. The featured part is a spherical disc, which controls the flow through it.

And there is a hole or port in the middle of the sphere. In fact, the two end of the valve determines a lot. When the two ends of the valve in line, flow will occur. And when the valve is closed, the hole is perpendicular to the ends of the valve, and flow is blocked. During this process, the handle or lever will do a great favor being inline with the port position Globe valve.

Basing on particular specifications and easy operation, ball valves are used extensively in industry as a result of versatility and wide range of supporting pressures and temperatures. And sizes typically range from 0.5 cm to 30 cm. Generally speaking, materials for the body are metal, plastic or metal with a ceramic center. And the ball is often chrome plated to enhance the durability and make the valve work perfectly at shutoff.

In order to reach some specific industrial requirements, ball valves are further classified into several types. From the perspective of body types, they are single body, three piece body, split body, top entry and welded. It is to say that the classification is based on the number of pieces of the valve. Though there are different types of valves, the operation is similar. And from the perspective of the bore of the ball mechanism itself, there are also many styles.

They are a full port, reduced port, V port, trunnion and cavity filler ball valve. What's more, manually operated ones can be closed quickly. And some are equipped with an actuator that may be pneumatically or motor operated. Those valves are usually equipped with a positioner. By doing this, it is easy for it to transform the control signal into actuator position and valve opening accordingly. For example, multi-port ball valves are generally with 4 ways, or more. They are also commercially available. And for the driving air-powered motors from forward to reverse, the operation is performed by rotating a single lever 4-way ball valve. What else, one piece ball valves are almost always reduced bore, which are relatively inexpensive and generally are throw-away. And two piece ones are generally slightly reduced (or standard) bore, they can be either throw-away or repairable non slam check valve.

In words, some general ideas about the ball valves have come into your mind, I suppose. Hope they would be widely used in order to improve the industry, as well as our daily life.

votre commentaire

votre commentaire

-

Gate valves are generally used for all sorts of applications and are suitable for installation both above-ground and underground. It is necessary, not least for underground installations, to select the correct type of valve to avoid high replacement costs with non-slam check valve.

Gate valves are designed for an operation that is completely open or fully closed. They are mounted as insulating valves in pipelines and should not be used as valves for control or regulation. A gate valve operation is performed by either clockwise closure (CTC) or clockwise opening (CTO) of the stem rotating motion. The gate moves up- or downward on the threaded portion of the stem while working the valve stem.

- Reducing the torque requirement of the valve and allowing one-man operation in order to control the pipeline differential pressure

- A continual flow is permitted with the main valve closed and the by-pass open, preventing potential stagnation.

- Filling of pipelines postponed.

Swing check valve

When minimal pressure loss and a free bore is required, gate valves are often used. A typical gate valve has no obstruction in the flow path when completely open, resulting in a very low-pressure loss, and this design allows a pipe-cleaning pig to be used. A gate valve is a multi-turn valve, meaning that a threaded stem is used to control the valve. As the valve has to turn several times to go from open to the closed position, water hammer effects are also prevented by the slow operation.

It is possible to separate gate valves into two main types: parallel and wedge-shaped. A flat gate between two parallel seats is used by the parallel gate valves, and the knife gate valve built with a sharp edge on the bottom of the gate is a common type. Two inclined seats and a slightly mismatched inclined gate are used in the wedge-shaped gate valves.

Gate valves with a metal seating wedge were commonly used until the resilient seated gate valve was introduced to the market. In order to ensure tight closure, the conical wedge shape and angular sealing devices of a metal-seated wedge need a depression in the valve bottom. Sand and pebbles are thus embedded in the bore. Regardless of how thoroughly the pipe is flushed upon installation or repair, the pipe structure will never be fully free from impurities. Eventually, any metal wedge would therefore lose its capacity to be drop-tight.

Growing stems are attached to the gate, and as the valve is worked, they rise and lower together, giving a visual indicator of the position of the valve and making it possible to grease the stem. The threaded stem is rotated around by a nut and moved. This form is only suitable for above-ground installation.

In the gate, non-growing stems are threaded, and rotate within the valve with the wedge growing and lowering. Since the stem is held inside the valve body, they take up less vertical space. To indicate valve location, AVK offers gate valves with a factory-mounted indicator on the upper end of the stem. Non-rising stem gate valves are ideal for installation both above ground and underground.

votre commentaire

votre commentaire

-

Several folds are expected to increase demand and supply for industrial valves. In commercial building projects as well as automation projects, industrial valves predict applications. The industrial valve market has grown due to aggressive industrialization and the growth and maturity of industrial plants globally.

It is possible to categorize industrial valves into different forms, such as diaphragm valves, globe valves, gate valves, pressure valves, ball valves, check valves, butterfly valves, etc. There are various functions and respective working principles for these types of valves.

Valves for Gate

Gate valves are characteristically designed to operate in industries as insulation valves. They contribute to the regulation and flow of liquid through pipes (particularly that which is heated at high temperatures or cooled at dramatically low temperatures). Gate valves are often used in both domestic and commercial environments and are made of various materials, such as cast iron, stainless steel, forged steel, etc.

As they are used to constantly stop or start the flow of liquids, the material used is used to ensure the valve's strength, reliability, and durability. By raising a circular, rectangular gate out of the direction of the fluid, gate valves run. A gate valve's strength and capability are determined by the size of the diameter of the bore. Globe valves and Double block and bleed valve are considered to be one of the most common valves across a wide range of industries. In regulating and monitoring the linear flow of liquids, they find parallels to gate valves. By regulating the flow within the pipe by placing a movable plug within an immovable frame, globe valves work.

Ball walls

For industries that work with gases, Trunnion ball valve are an excellent choice, as ball valves provide foolproof sealing. Elevated pressures and temperatures may also benefit them. Since their sizes usually vary from 0.5 centimetres to 30 centimetres and they have a simple structure, it is easy to operate and fix ball valves. They have a bad throttling function that is known as both an advantage and a drawback. Owing to weak throttling, the ball in the valve doesn't quickly erode, and there is a smooth flow of particles. Ball valves open and shut quickly, and the multi-way mechanism is versatile.

Butterfly Valves

Butterfly valves have limited flow-regulation capabilities. By rotating the valve by 90 degrees, they can easily operate. In the closed position, the metal disc is a critical element in the valve as it is located perpendicular to the substances' flow. Via intermediate rotations, the control of the flow of the liquid is permitted. To be able to operate electronically, pneumatically and even manually, these types of valves are programmed.

The demand for Industrial Valve is expected to expand due to an expansion in the Gulf Cooperation Countries (GCC) of the oil and gas industries. Development in the iron and carbon black industries is also increasing the market for pipes and thus increasing the worldwide demand for valves. In addition, high demand from manufacturing industries in emerging APAC nations for predictive maintenance is boosting the industrial valve industry.

votre commentaire

votre commentaire

-

Valves are merely devices used to control or regulate flow by opening, terminating, or partially preventing lines. The valve is essential in everything, from removing soap from the dispenser to starting the stream.

Only a suitable industrial valve expert can become a tube expert. Without the valve, you cannot control the circulation of the tube.

Valves are essential in any plumbing system and are used to control the circulation and pressure of contents such as oil, gas, fluids, and smoke. These are valve types and some of their features.

Purge valve series PGV

The purge valve is part of the vehicle's Evaporative Emission Control (EVAP) system. The EVAP system shuts off the fuel vapor in the fuel tank from its escape to the atmosphere. The EVAP system locks out fuel vapor from the gas container and temporarily stores it in the grill tube. Here, the bleed valve's function is to control the amount of fuel vapor removed from the grill tube. It is a very good Industrial Valve.

Ball valve

Ball Valve-Series-BV101-Ball Valve-Series-BV103-Ball Valve-Series-BV105

The ball valve, which uses a ball-shaped disc to control the flow, is equipped with a 1/4 turn rotary motion valve. When the valve is withdrawn, the ball gap remains aligned with the body inlet, allowing it to pass through. Double block and bleed valve are also famous nowadays.

Since the seat is made from soft parts like Teflon, balls are commonly made from various metals. Due to the mixture of components, the ball valve can operate in the temperature range from -200°C to 500°C.

Mainly used for air, smoke, and fluids, the ball valve turns on and off quickly, has little torque, and has a decent finish. The only drawback of these valves is the lack of choke quality available.

Bleed valve

The massive duty gas generator uses an air compressor bleed valve to protect the axial air conditioner press from deceleration and surge conditions during startup and shutdown. Usually, these valves only activate during acceleration to rated speed and deceleration to rated speed. The new heavy-duty gas generator with a complex combustion program setup, developed to limit harmful smoke emissions, features an air compressor bleed valve during very delicate operation to limit air entering the chamber. Also used for combustion.

Lever valve

The toggle valve on and off settings determine whether fluid passes through the valve. A well-designed toggle valve should be of a quality that completely stops circulation when closed and allows for almost unchanged circulation at the start. The primary purpose of the toggle valve is to reduce the effect of tension in the initial position. A toggle valve can be used on the GC to explain the process of eliminating the use of a technical valve on the stove and quickly adding it to the stream. You can also buy a Floating ball valve.

So its valve has its own function and benefits in different industries.

votre commentaire

votre commentaire Suivre le flux RSS des articles

Suivre le flux RSS des articles Suivre le flux RSS des commentaires

Suivre le flux RSS des commentaires