-

Different manufacturing materials, different designs, applications, and variable uses ... industrial valves can be of very different types. The different sectors in which they are useful to demonstrate that these devices are extremely useful cover a myriad of different needs related to fluid management. In this article, you will know the main types of valves that exist, as well as their main characteristics and how they work.

These are the main types of industrial valves used today:

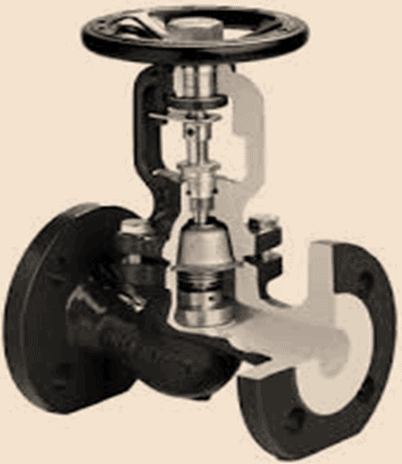

Globe valves. This device is used to control the flow of liquid in a pipeline. It is made up of a movable disc-type element and a stationary ring seat. The body is usually spherical in shape, although it is also shaped like a 'Y,' 'T,' or a balloon. These types of industrial valves are designed to offer complete tightness, as well as high flow effectiveness. They stand out for their durability, something related to the type of material in which they are.

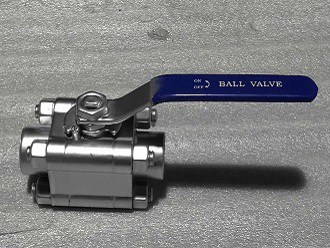

Ball or spherical valve. Also called ball valves, they are characterized by the fact that inside the house, a sphere with perforations through which one is produced to regulate the passage of fluids from the pipes. At the moment when the valve is in the closed position, the perforation is perpendicular to the inlet and outlet. However, when the ball valve is open, there is an alignment between the inlet and outlet of the valve itself. To easily distinguish the position of the device, a handle is used, which is used to manoeuvre with it. They can be operated manually or automatically and can have a one-piece, two or three-piece body. the non slam check valve is also good for industries.

Gate valve. The procedure by which they open the way to a liquid is the raising of a blade or gate that can have rectangular or round shapes. They are not used for regulating, but for uninterrupted clean fluid flows. The opening and closing process causes frictional wear and is slow.

Needle valves. These valves facilitate efficient regulation of a high-pressure liquid for small pipes. They have a conical shaped closure shaft that acts as a plug-in a reduced opening. These valves are especially appreciated in the hydraulic sector, where they are used in bypasses, route cuts, and diversions as bypass, directing the flow to ball valves or butterfly valves as a previous step to introducing the liquid in turbines or engines. These valves are immune to strong contrasts between different pressures and have a good seal due to their design and stability. Bellows valve is also famous.

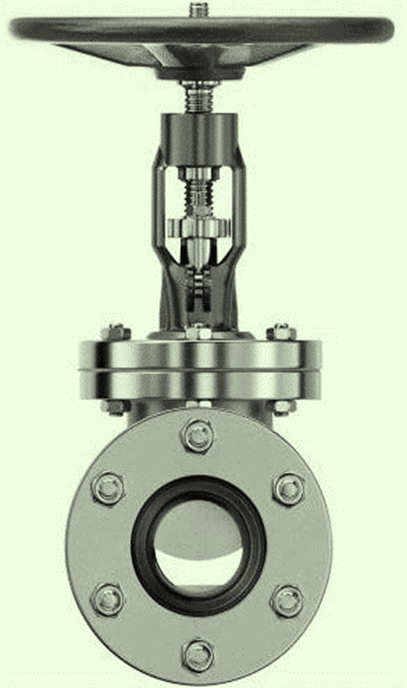

Butterfly valves. Useful to allow or prevent the passage of liquid. They have activated automatically or with actuators. These valves open with a 90º rotation of the disc. Globe valves are widely used.

Check valves. Also called non-return, check, or single flow, they close the flow of fluid in one direction and circulate in the opposite direction. One of the advantages it offers is that it prevents pump stripping and water hammer. There are several different types of check valves, such as swing flap valves, spring valves, ball check valves, and piston valves.

votre commentaire

votre commentaire

-

Valves are very crucial in controlling gas or liquid flow in almost all processes and systems. Though they are in common, selecting the right valve seems to be confusing and time-consuming. You have to gather basic information on system performance requirements. This will help you find the right valve easily. Here we list some tips on how to match valve specifications with these requirements.

Size and type of the valve

Select the perfect valve type because every valve has to do one or more basic functions like shut off the flow, mix flow, pressure relief, adjust the flow, backflow prevention, and many other functions. It is the function that determines the design of the right valve types. Some common valve types include the Slide gate valve, toggle valves, check valves, Knife valve, and relief valves, and so on. You have to properly size the valve because matching the valve’s size is essential to ensure the expected flow through the system.

Materials of construction

Valve materials must be compatible with the liquids or gases flowing through it. So, you have better understand the chemical compatibility needs. Plastic valves better resist corrosive chemicals better than the standard metal valves.

Performance norms

Check the temperature, pressure requirements, and also the range of the system where the valve will get installed. The metal-coated swing check valve seems to resist higher temperature and pressure than plastic valves. They are also suitable for pressurized gases because they are stronger than plastic valves.

Check for special requirements

Ensure that the new check valve will work as you expect. Consider the response time needed and the cracking pressure required to open the valve. Some basic check valve designs need positive downstream pressure to open. They are called as normally closed check valves. Other designs need positive backpressure to close and these are called open check valves. You have to choose between these two to enhance check valve reliability. You can base the decision on whether the valve is usually open more or closed more during system operation.

Maintenance

Never forget to consider the ongoing maintenance because valves demand on-time maintenance. This is significant for both application stability and valve reliability. Globe valves, for example, resist jamming, clogging, or malfunctioning. Valve connection type plays an important role in easing and enhancing the speed of repair or replacement.

Where to start?

If you know where to start, you will make the valve choice easier and faster. There will be issues like application norms, operating conditions, and chemical compatibility. If you begin with basic valve requirements, you can simplify and speed up valve selection.

There are a lot of valve manufacturers and suppliers to buy specific valves like Bellow seal globe valve. You have to choose the most reliable and affordable supplier to get premium quality products for your systems. Look at online sources for customer reviews and testimonials to help you with decision making.

votre commentaire

votre commentaire

-

Are you in the market for an industrial valve to protect your compressors or blowers? Or maybe looking for a premium quality safety valve for a power generating system, choosing the best supplier is the most significant decision that you have to make. If you develop a relationship with an authentic valve company, you can be sure of getting the right products, at the most feasible price, to meet your needs. Those products are well maintained throughout their functional life cycle.

Here we discuss the 5 most important things to consider when choosing a valve supplier.

Stock on hand

Check for the amount of inventory the supplier carries on hand. This number is significant because it indicates the time that you will take to receive the ordered valves and parts. This can be of extreme importance during planned outages or during an emergency. If you contact a Trunnion ball valve supplier that has a large inventory on hand, you can increase your chances of receiving them as and when needed.

Preventive maintenance services

Regular maintenance is essential to achieve high performance out of your valves and products, for example, double block and bleed valve. Though recommendations for preventive maintenance is varying, you should search for a supplier that better understand your needs and can do maintenance jobs with little disruption to your functions. Check whether or not the supplier uses any kind of valve management software to centralize valve history and maintenance data for identifying maintenance and repair needs.

Repair services

Sometimes well-maintained valves require repair, so search for a valve repair that can take care of a wide range of valves, both in the field and in the shop. Check whether or not the supplier is a member of any valve repair council. If you are dealing with pressure relief devices, ensure that your supplier is certified by the federal board for repair services. These designations are necessary because they guarantee that your valve will be taken care of with its real specifications.

Besides industry certifications, search for a supplier who has a team of technicians with excellent factory training experience. For example, particular centers are authorized to repair pressure relief valves, Floating ball valve, etc. So, learn more about valve certifications and choose a supplier that has a team of well-certified technicians.

Actuator sales and services

Actuators and valves work hand in hand. If you want your supplier to help you choose the best products for your process from beginning to end, then choose a supplier that better understands the relationship between actuators and valves and can offer you services for both types of products.

Dedication to safety

Safety is the major issue related to gate valve installations, and regulations related to safety norms change frequently. There could be a systemic lack of supervision on gas pipelines, so the national safety board might issue new and improved safety recommendations to influence regulations at state and local levels. If you want to ensure your projects in compliance with regulations, look for a valve supplier that better understand the regulatory landscape and showcase a commitment to safety.

votre commentaire

votre commentaire

-

Valves are considered to be simple devices which are used to control the flow of fluid by obstructing the passageway or the pipes. These can be found in many places where the fluids flow and it can include your bathroom as well specifically faucet. Water flows out when turning the handle, turn it back and water will stops flowing. Let’s know about different types of valves:

The main function of Slide gate valves is to keep the pressure of the water under control. Due to continuous water pressure there is more chances of wear and tear of any part of the valves increases. As such, it is generally suggested that the valves need to be thoroughly checked before only for trouble free and smooth functioning. However, due to one reason or any other if the valve get damaged it should to be replaced on urgent basis so that the risk factor of major problem can be minimize.

Knife valves are basically made for on and off and isolation services in the systems with high content of suspended solids. These valves are especially important for handling viscous, corrosive, slurry, and the abrasive media. The valves provide a minimised pressure drop in the fully open position, these valves are easy to actuate, the weight is relatively low and these are cost effective.

Globe Valves are spherical in shape as per the name. These valves offer greater exactness than the other types of valves when it comes to the regulating flow. These are used in applications where the flow needs to be finely tuned. They have a structure of plate with a hole in it, and a disk or a plug wholly or partially fits into the hole, slowing and stopping flow.

Swing check valves are in less used when it is compared with the other types of widely used valves. Under the reverse flow conditions this swing check is held firmly against the valve seat and preventing system losses. These valves are good for keeping the pump aware when the power is gone. They help the water to flow back from the filter into the pond. These can be buy in many sizes and in different types.

A Bellow seal globe valve has a solid structure and is the one kind of control valve which help to balance the pressure. To ignore the leakage of the valve stem, valve adopts the structure with the bellows instead of stuffing boxes normally used for the ordinary valve or the structure with both stuffing and bellows boxes. It is basically suitable for the pipelines of explosive and hazardous media, steam and flammable. Moreover, because of bellow's properties of aging and deformation resistance, the bellow seal valve overcomes the most common latent defects, which includes temperature sensitivity and the aging of the stuffing box, and these defects are taken care by the valve which are sealed by packing. It is operated as an obstruction between the fluids and the air. At the same time, the valve can also prevent the fluids leaking to the air and guarantee on zero leakage of pipelines.

votre commentaire

votre commentaire

-

As we all know that pipelines helps to efficiently transport huge amounts of liquids and gases collectively known as fluids. But pipelinerequires a regulating body which can decide the amount of the flow and when to start and stop the flow for their efficient working. This is the time where, valves come into picture and are the regulating body whichhelps to control the flow rate and act as a switch which can start and stop the flow.Valves also playing an important role in the movement of fluids in many industries such as oil and petrochemicals, pharmaceutical industries and food and beverage industries and also become an important parts of many types of machinery too.

Industrial Valves are mechanical devices whichblock pipes or passages of gasses and liquids either wholly or in some measure to control the flow rate as needed. In our daily lives we come across many valves, but probably we never noticed them. The taps which we open and close to control the flow of water is also a valve eventhe regulators which we use to control the gas flow from our gas pipelines are also valves. Also it can be found in cookers as well.

All valves are generally quarter turn valves as we have to turn the lever by 90 degrees to start and stop the flow and use a hollow, pivoting and perforated ball which is also called as a floating ball valves. And from this valve the flow of fluids takes place. When the lever or handle is moved to 90 degrees, the hole of the ball gets line up with the pipe opening and help to start the flow. When the lever is turned by 90 degrees again, the hole turns around and the ball will block the opening of the pipe that helps to stop the flow.

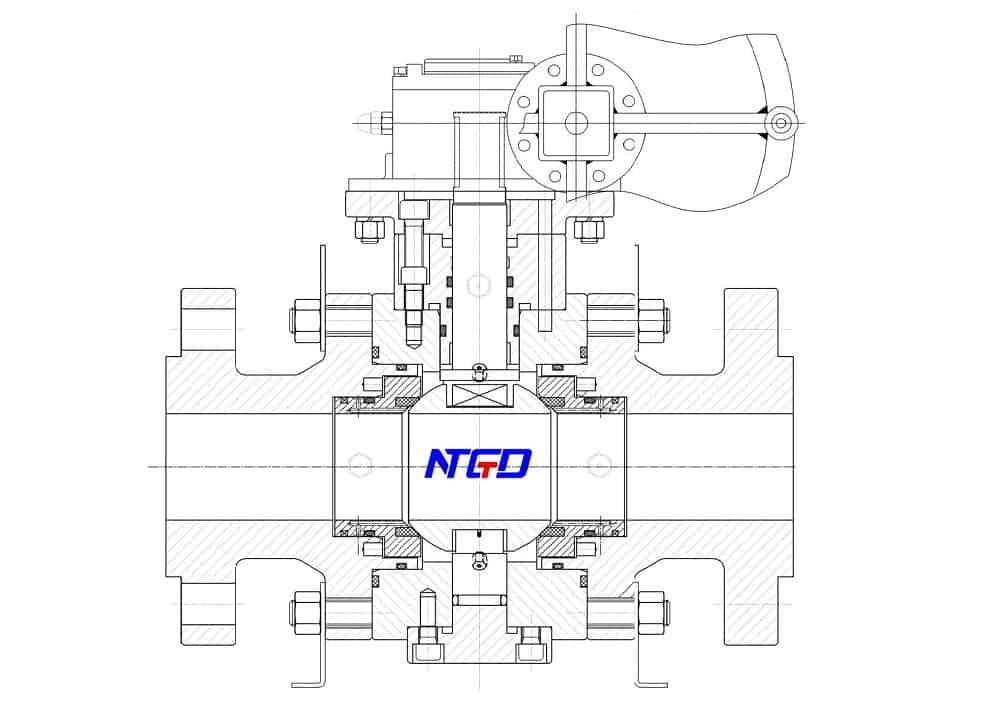

A double block and bleed valve is a single valve with two seating surfaces which are,the closed position, and that provides a seal against the pressure from both the ends of valve with a means of vending or bleeding the hole between the seating surfaces. They are mostly used in the oil and gas industries, but they can also be helpful in other industries as well.

There are different types of ball valves which are extensively used in numerous industries and all depending upon to their designs, sizes and the pressure handling capacities. Most of the common ones are reduced port, cavity filler,Full port, V port, trunnion ball valves (have an anchoring or disc above and below the valve which help in high pressure flow rate) and the multiport valves.

Gate Valves are made to serve as an isolation valves. These kind of valves help to control the liquid flow through the pipes. These valves affixed to the pipelines to start and stop the water flow or any other kind of liquid. These are used for many purposes and they can be seen mostly in homes and commercial centres. Different materials such as cast iron,stainless steel, forged steel, alloy steel etc are used to manufacture these kind of valves.

votre commentaire

votre commentaire